Operator Comfort

Spacious Cabin

The cabin offers a wide, unobstructed view of the work area, complemented by an ergonomic console and a clear touch display, ensuring superior visibility and effortless control of the forklift.

Ergonomic Fingertip Controls

The fingertip lever controls are ergonomically positioned for effortless and precise operation of the attachment and mast functions, enhancing operator comfort and efficiency. These controls are standard on the Konecranes tyre handler.

Enhanced Joystick Control (Optional)

Upgrading to the electronic servo joystick improves operator control and comfort. Conveniently positioned thumb buttons on top of the joystick enable effortless operation of the mast and tyre clamp functions, including gripping, lifting, and rotating.

Perfectly Positioned Buttons

All essential forklift controls, including exterior LED lighting and windscreen wiper functions, are strategically positioned within easy reach for operator convenience.

Silent Operation & Less Vibrations

The E-VER electric tyre handler produces 50% less noise and vibration when compared to standard diesel models, making them more comfortable to operate.

Adjustable Steering Column

The steering column height can be easily adjusted to fit the operator’s needs, promoting proper posture and enhanced comfort.

Adjustable Suspension Seating

Adjustable settings enable operators to customise the seat position, height, and lumbar support for optimal comfort and ergonomics.

Ergonomic Pedal Positioning

The pedal includes one standing accelerator pedal, two standing brake pedals and an electric declutch as standard.

Advanced Climate Control

The OPTIMA cabin includes a powerful heating, ventilation, and air conditioning system (HVAC) for maximum comfort for the operator. This climate control is integrated and controlled within the touch display screen.

Productivity & Performance

Lithium-Ion Battery

The tyre handlers Lithium-Ion battery provides high performance, zero emissions and minimal maintenance. The battery can also reduce costs by up to 23% compared to a diesel forklift. Furthermore, businesses can reduce downtime using a fast-charging station, which can deliver a full charge in approximately 45 minutes.

Quick Acceleration

The tyre handlers 110kW motors produce instant torque with rapid acceleration when needed. This makes it highly manoeuvrable and enjoyable to drive for the operator.

Dynamic Driving

The tyre handler can handle slopes up to 20% faster compared with the diesel model.

Quick Lifting Speeds

The electric tyre handler produces faster lifting speeds compared to the diesel model, including up to 25% faster on 10-18 tonne models, and 10% faster on 18-25 Tonne models.

Rugged Tyre Handling Attachment

The specialised tyre handling attachment enables the safe and efficient handling of Off-the-Road (OTR) tyres weighing up to 16 tonnes. Designed to accommodate tyre diameters from 1500mm to 4020mm, the attachment offers a ±35º rotation for enhanced manoeuvrability. Side arm pads ensure a secure grip with a 90º tipping rotation, while automatic hydraulic fallback arms prevent the tyre from tipping toward the cabin for added safety. For greater flexibility, an optional override feature allows manual disengagement of the fallback arms during tyre tipping operations.

Eco Friendly

The fully electric drivetrain reduces energy consumption and ensures zero emissions. This makes it perfect for both indoor and outdoor operation.

Smart Connected Display

View real time information about the tyre handlers most vital components and performance, all from a modern 7-inch touch screen display. This includes ECO-drive and fuel management, electronic overload and safety system, productivity counter management and much more.

Regenerative Breaking

Regenerative breaking allows energy to be recovered and stored for later use.

Heavy Duty Masts

The wide, heavy duty mast is optimal for lifting and provides excellent visibility for the operator.

Durable Chassis

The intelligent and durable Konecranes box-type chassis is a leading design offering one of the strongest chassis on the market. This provides higher lifting capacity without reductions at high lift heights.

Auto Engine Shut Down (Optional)

The engine can be automatically switched off when the tyre handler has been sitting in idle for a period. This time can be preprogrammed to minimise fuel wastage when the operator has stepped away and left the machine running.

Fallback Arms Override (Optional)

An override system has been integrated with the onboard touch display that allows the operator to manually disengage the fallback arms. During tyre flipping, the fallback arms can be raised for 30 seconds to allow the tyre to be safely dropped. This prevents the tyre from impacting and damaging the attachments fallback arms.

Safety

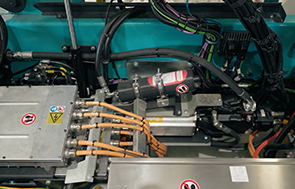

Battery Protection

The Lithium-ion battery packs are mounted within a protective frame and positioned in the centre of the chassis. This helps minimises the risk of physical impact and damage, which could lead to a short circuit or overheating.

Battery Monitoring

The battery is closely monitored and temperature controlled by the forklifts advanced systems for optimal efficiency.

Alarm System

To increase the safety of the operator and surrounding pedestrians, an effective fire alarm and suppression system is installed within the tyre handler.

LED Lightning

LED lighting clusters on the cabin roof, mast and forklift provide very bright and directed light that allows safer operations in low light conditions.

Anti-Slip Steps

Anti-slip steps make it safe to access the cabin in any weather conditions.

Mine Spec Steps and Handrails (Optional)

To further enhance safety, bright yellow anti-slip tread nosing can be mounted on the stairs for greater grip in dusty and wet site conditions. Handrails can also be mounted to ensure three points of contact when entering and exiting the tyre handler.

Auto Park Brake (Optional)

This safety feature automatically switches on the electronic handbrake if the operator leaves the seat before they have applied the handbrake. This enhances safety by preventing accidental movement of the machine.

Perimetre Lighting (Optional)

Bright safety perimeter lights are effective at creating pedestrian exclusion zones. Furthermore, blue spot warning lights can also be attached to warn pedestrians when the forklift is approaching, particularly when the forklift is manoeuvring around corners or blind spots.

Wireless Clamp Pressure Monitor (Optional)

This innovative safety feature allows operators to gauge how much pressure is being applied when gripping a tyre. It works by wirelessly transmitting the hydraulic pressure of the tyre clamp to the receiver, which can be monitored on a dash mounted digital display within the cabin. This gives the operator the exact pressure of the clamp which they can now reference to the correct pressure required.

Furthermore, if the tyre starts to slip or the clamp loses pressure, an audio alarm automatically alerts the operator and ground personnel of the danger. This enhances safety be ensuring no one is in the line of fire.

Sequential Lighting Safety System (Optional)

This safety light system allows an operator to signal to ground personnel when it is safe to approach the tyre fitting area. Using the onboard touch display, the operator can quickly switch from a red light (danger) to a green light (safe), which helps to reduce risk in tyre maintenance.

Magnetic Wireless Cameras (Optional)

During tyre handling, operators can increase visibility by mounting up to three magnet wireless cameras on the tyre clamp attachment. The feed from these wireless cameras can then be viewed through a colour display within the cabin. The camera battery can also be swapped out quickly for uninterrupted use.

Blaxtair Pedestrian Detection Systems (Optional)

Automatically detect pedestrians in real time with intelligent 3D stereo cameras that can be retrofitted anywhere on the tyre handler. These cameras help minimise accidents on site by instantly warning the operator when a pedestrian has entered the danger zone.

Perimetre Lighting (Optional)

Create exclusion zones for pedestrians with safety perimeter lights. Furthermore, blue spot warning lights can also warn pedestrians when the forklift is approaching, particularly when the forklift is manoeuvring around corners.

Isolator Switches (Optional)

A lockable starter isolator switch can be installed to safely prevent operation of the tyre handler when not in use. A battery isolator can also be used to prevent unwanted battery drain and to further boost safety.

Fire Protection (Optional)

Fire extinguishers can be mounted on both sides of the exterior cabin. This adds greater safety in the event of an emergency, ensuring the operator or ground personnel can act quickly.

Servicing & Maintenance

Simpler Maintenance

With fewer components and common electrical modules, the E-VER tyre handler offers easier maintenance. Furthermore, with no engine and transmission, the E-VER is 23% cheaper to service than a traditional diesel model.

Full Braking Power

Continuous oil cooling is provided to ensure full braking power in any situation. Less maintenance is required which further reduces costs.

Fleet Maintenance

TRUCONNECT®

Remotely monitor and track real time usage on your tyre handler using Konecranes TRUCONNECT®. Track information such as battery consumption, travelling distance, hours and speed, safety alerts and much more. Learn more about the TRUCONNECT® fleet management solution.