Operator Comfort

Remarkable Visibility

The operator can safely operate throughout the worksite with exceptional range of vision, thanks to the cabin’s large, lowered windows, no corner posts, and curved panels. Take a look at a 360 degree view of the cabin.

User Friendly Ergonomics

Monitor all the vital information of the container handler with the 7-inch touch screen, and easily control the container handler with the smooth finger-tip levers.

Operator Customisation

Customise and adjust to the operators needs and preferred style. Options include mini-wheel steering, lever steering, seat adjustments and much more.

Productivity & Performance

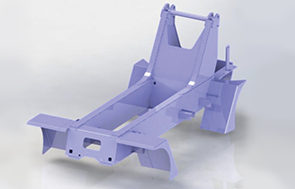

Strong Chassis

Konecranes box-type chassis is one of the strongest chassis on the market and is the foundation of Konecranes long-lasting high performance.

Excellent Lifting and Stability

With the contain handlers wide drive axle and long wheelbase it effectively combines to provide excellent stability. This design provides reliable lifting with heavy loads, even at heights, which increases productivity.

Lower Cost

Fuel Efficient Engine

The container handlers’ powerful engine provides extra high torque at low revs with reduced fuel consumption and low noise. The certified low emission engines are cleaner and help to reduce running costs.

Maintenance Free Brakes

Continuous oil cooling in the container handlers’ brakes provide full braking power in any situation. This effective cooling system ensure the brakes require less maintenance than standard brakes which further reduces costs.

Safety

Intelligent Alarm System

The fire and suppression system provides peace of mind for the operator. The system works by either automatically discharging through on-board sensors, or manually by the operator. In either case an alarm is sounded to warn the operator to vacate the container handler.

NearGuard Warning System

Konecranes award winning NearGuard safety system provides a safer work environment by warning operators ahead of time to imminent collisions. By utilising Radio Frequency Identification (RFID) technology, collisions with obstacles and personnel are minimised by an audible alarm and dashboard display warning which advises proximity.

Servicing & Maintenance

Sophisticated Hydraulics

An optimum balance between the engine power and hydraulic demand is provided through a smart load sensing hydraulic system with variable piston pumps. This helps to reduce wear on the engine, gearbox and hydraulics, as well as minimise the amount of fuel consumption and environmental impact.

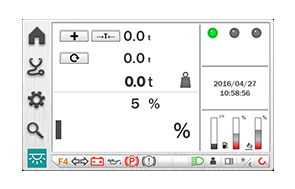

EMC Master

The Electronic Machine Control (EMC) is an intelligent system that provides the forklift operator real-time information on the trucks performance. The dashboard screen displays full truck monitoring of the engine, transmission and hydraulics, which can help to plan maintenance and minimise downtime.

Fleet Maintenance

Truconnect

Truconnect® enables you to remotely monitor and track the real usage of your lift trucks including hours, fuel consumption, travelling distance and speed, safety alerts and much more. This is a great tool for scheduling forklift maintenance actions and consequently improving the fleet’s uptime. Learn more about the Truconnect fleet management solution.